I have decided to start producing anvils in a modified A series steel. I have been working over the last year with several variations of air hardening steel and I am seeing promising results with this new type. This A series steel provides deep hardening with ample hardness in some cases reaching 63 HRC before the tempering cycles.

In the future I may start doing my own heat treat and try a few other steels (just because I like to try new alloys).

The anvils have a tempered hardness of 58-60 HRC over the mass and each anvil is

individually tested for assurance. The anvils are through hardened so

you do not need to worry about a face that dishes.

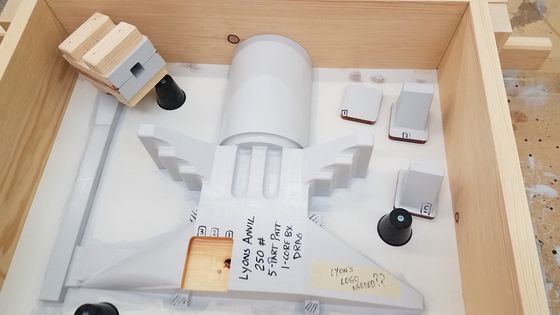

I have also tried to reduce the cost of the anvils without any degradation in performance. One way of doing this was to make my 220+ pound anvil pattern have multiple side shelf orientations. This makes one pattern produce three different anvil configurations. The only trade off is you will see a faint line where the different side shelves or no side shelf inserts fit( see pictures at bottom). Another way of reducing cost was to have the anvils Blanchard ground instead of surface ground. The surface grinding gives a flat, smooth, and fine finish. Blanchard grinding gives a flat finish with a swirled scratch pattern that is more random with a few errant scratches of the same grit here and there. I can still put a fine finish on the tops but it adds to the cost. Blanchard grinding gives a flat surface and sacrifices nothing with respect to performance. It

is important to note, toughness on its own is not ideal for an anvil.

An example of this would be mild steel which is tough but dents easily.

Moreover, strength on its own is not ideal for an anvil. For example,

high hardness high speed steel is very strong and will resist

deformation but will tend to chip or crack when yield force is reached.

With that in mind, these anvils are tempered to a hardness which

provides the absolute best toughness to strength ratio for this modified

A series steel.

As of

right now I have patterns for 457 pound anvils and 220+ pound anvils.

The 220+ pound anvils have a choice of: no side horn, side horn flush

with top, or side horn recessed from the face. Eventually the 457 pound

anvils will also have this side horn option. However, as of right now

the 457 pound anvils all have a recessed side horn as pictured to your

left.

I

will keep 220+ pound anvils in stock. If 457 pound anvils are in demand

I will start stocking them also. For any anvil ordered that is not in

stock there will be a 50% deposit and roughly an 8-10 week wait.

All anvils are made in the U.S.A.